Modern refinery operations process an incoming crude oil stream into multiple high-value product streams, some needing additional processing. Both high-value and byproduct streams require periodic sampling to ensure that the refinery processes operate within specified parameters.

Due to the processes' often high pressure and chemical nature, obtaining a representative sample safely is essential.

CHALLENGE: SAFELY SAMPLING SOUR WATER

In the petroleum refining process, one of the main byproducts is wastewater rich in hydrogen sulfide (H2S) and ammonia, commonly referred to as sour water. The term sour water is used because – in addition to contaminants such as NH3, solids, chlorides, mercaptans, and phenols – H2S, or hydrogen sulfide, is present in the water stream. Plants sample their sour water to measure these chemicals. They must be removed to prevent contamination and corrosion.

Accurate measurement of hydrogen sulfide and ammonia concentrations at the outlet of the H2S stripping unit, also called the stripper, provides critical process validation information and allows for corrective action in the event of stripper failure.

Because sour water stream requires special handling, a sampling system must use exhaust and ventilation equipment to reduce hydrogen sulfide levels. The system also needs to be non-sparking, grounded, corrosion-resistant, separate from other exhaust ventilation systems, and explosion-proof.

In the absence of this type of sample station, the operator taking the sample needs to follow stringent PPE (personal protective equipment) requirements, including respiratory protection and other personal protective equipment (PPE), such as eye protection and possibly fire-resistant clothing. Respiratory protection includes:

- For exposures below 100 ppm – An air-purifying respirator with specialized canisters/cartridges for hydrogen sulfide. A full-face respirator will provide eye protection.

- For exposures at or above 100 ppm – A full-face pressure demand of a self-contained breathing apparatus (SCBA) with a minimum service life of 30 minutes or a combination full-face pressure-demand supplied-air respirator with an auxiliary self-contained air supply.

Both options are problematic for end users. If samplers do not meet unique design requirements, the operator taking the sample must suit up in PPE gear, which is time-consuming, hot, cumbersome, and uncomfortable. Most of all, taking a sample in this manner is not necessary, as better, safer, and more effective solutions are available for refinery sampling.

SAFE SAMPLING SOLUTIONS

After evaluating these customer difficulties, our engineers decided a new approach was possible. Sentry's MVD, Cobra M, and Cobra SS manual low-emission samplers were developed to provide a safe yet straightforward sampling solution by collecting samples in a bottle with a septum.

These designs were modified to locate the sample container portion within a windowed enclosure for our refinery customers. This allows the operator to operate the valves and deposit the sample into the contained environment. The enclosure is provided with an eductor system. It will enable any H2S gas to be purged from the enclosure before operator exposure.

The adaptability of these samplers is high as each can be designed with a wide variety of bottle, septum, and needle/tube stub/stinger configurations and sizes. Because some customers have issues with plugging, a standard solution is a half-inch MVD tube stub and Cobra stinger design with an enclosure and educt system.

Although the bottle septums are self-sealing, some operators believe more protection is needed during transport. Therefore, some choose to remove the cap with the pierced septum and replace it with an intact cap. This causes the risk of volatile gases escaping, threatening the operator's safety and the environment, and compromising the sample integrity.

The Sentry No-E Double Cap takes care of this issue with a cap-on-cap design that features external threads on the existing cap to allow another cap on top of it – so the bottle can be completely and safely sealed.

This allows the user to cap and transport the sample bottle safely, protecting the operator's safety and environment while preserving sample integrity.

Together, these solutions simplify operation and protect from H2S exposure at an affordable cost. Operators do not need to suit up in extensive PPE, reducing the time and hassle of sampling and increasing safety without limiting specialized process needs.

Written by Horacio Salinas, Jr.

Related Posts

Corrosion

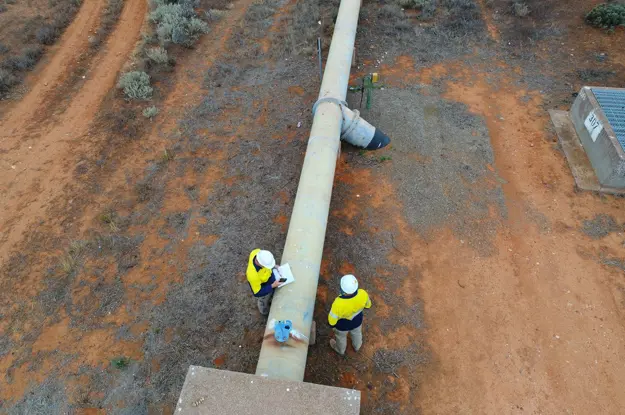

PHMSA Mega Rule: Your Guide to Navigating the New Regulations

The pipeline Industry has heard a lot about the Pipleine and Hazardouse Materials Safety Administrations (PHMSA) three rules to reduce the frequency of pipeline failures. Now, the third and final rule has been released.

Read More

Corrosion

Internal Corrosion Monitoring: What You Need to Know

Pipelines carrying oil and gas experience internal corrosion when water is present inside the lines.

Read More

Corrosion

What are Atomizers and Do I Need Them?

Corrosion is a significant contributor to gas and oil pipeline failures. That is why many oil and gas companies implement chemical treatment methods to eliminate corrosive contaminants within gas pipelines. But chemical efficiency can be drastically affected by improper injection methods.

Read More

Mitigate Process Damage

Sentry's low-emission samplers helps protect your operation and employees from caustic materials.