5 Important Tips for Cleaning Your Sampling Equipment

Cleaning sampling equipment used in food production is very important.

Food producers need to have confidence that their automated samplers are cleaned and maintained properly to eliminate contamination and potential recalls and their associated costs. Thorough cleaning and sanitizing of food-handling machines, and equipment, including food and beverage samplers is a requirement of a robust hazard analysis and critical control points (HACCP) plan.

Cleaning your product sampling equipment is part of a complete sampling program compliant with ISO TC34, FDA, local and product specific standards and guidance. Improperly cleaned or maintained sampling equipment and sample containers can introduce bias to the sampling process leading to results that are not representative of the process. A properly designed sampling system and process should include a detailed cleaning specific to the product sampler and sampler accessories.

Food contact surfaces including samplers need to be cleaned as part of a facility’s standard operating procedures for sanitation. It’s important to establish and follow standards for hygiene and cleaning procedures to meet your facilities’ needs and train all operators and maintenance staff in those procedures.

Follow these 5 tips about how to clean food and beverage sampling equipment to prevent contamination.

1. Always Follow Instructions

When cleaning or maintaining your food and beverage samplers, always follow the equipment manufacturer’s recommendations and plant safety procedures including wearing required personal protective equipment according to plant regulations. The cost of damaged parts when a sampler is cleaned, maintained or repaired improperly by untrained personnel can lead to downtime and more cost. With proper training and familiarity with the sampler, cleaning and maintaining a sampling solution becomes easier and faster.

2. Schedule Regular Cleaning and Maintenance

Cleaning on a regular maintenance schedule helps keep equipment sanitary and up to date with the latest hygiene standards. Create and follow a definitive schedule for cleaning and inspection to ensure safe, accurate product sampling operation. On continuous duty installations, a sampler should be checked once a day for proper operation.

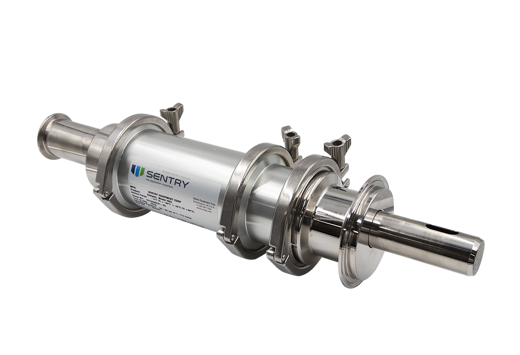

Operating an accurate and valid installed product sampler is critically dependent on effective cleaning procedures. The latest Sentry hygienic samplers, the HPR and HRX, incorporate design, materials, surfaces and finishes to allow effective cleaning. When a sampler is cleaned, it should be inspected for wear and damage that can affect its continued successful operation. It should be checked for proper operation to ensure that any wear is detected for preventative maintenance.

3. Inspect for Wear and Damage

Samplers may wear with use, and therefore need to have parts replaced. Powder and bulk solid material can be particularly hard on sampling equipment due to the large and hard particle composition of some materials. These materials are abrasive and can produce large quantities of dust, which can be hazardous to operators and damage equipment. Friction can develop between the auger and the sampler’s internal tube wall as well, which can cause damage to the sampler. If damage causes the sampler to malfunction it should be repaired or replaced.

While cleaning, inspect the sampler to ensure all connections, clamps and fasteners are firmly tightened. Loose or improperly secured connections can cause leaks or damage to the sampler.

4. Don't Make Modifications

A product sampler or its controller should not be altered. A sampler shouldn’t be welded, machined or modified in any way to change its operation to compensate for wear. In addition, only use proper OEM replacement parts, and always consult the sampler manufacturer with questions about maintenance, repair or if changes need to be made to its installation or operation.

5. Get Professional Help When Necessary

Food and beverage sampler cleaning may require complete equipment disassembly, inspection and in some cases certification. If in-house maintenance technicians are not up to this task, repairs, factory certification and testing of product samplers should be made by professional, factory-trained experts. Outsourcing service can minimize rework and damage to parts caused by untrained maintenance personnel.

Sentry ProShield Lifecycle Services provides technical support to ensure maximum sampler uptime. Highly-trained, factory authorized service technicians can help you maintain clean, safe and reliable sampling solution from installation to routine maintenance or replacement in any processing environment.

Written by Sentry Equipment

With proven sampling expertise since 1924, Sentry products and services provide business operations the critical insights to optimize process control and product quality. We deliver true representative sampling and analysis techniques to customers around the globe, empowering them to accurately monitor and measure processes for improved production efficiency, output and safety. Standing behind our commitments, we are determined to tackle any application, anywhere.

Related Posts

Preventative Maintenance

Monitoring Sodium in Power Plants

An increase in sodium measurements may identify unwanted dissolved impurities. When coated on the boiler turbine blades and heat exchanger surfaces, these impurities can cause catastrophic problems in power plants.

Read More

Preventative Maintenance

The Advantages of Chlorine Dosing to Control Biofilm in Industrial Cooling Systems

Microorganisms are organisms of microscopic size, which may exist in its single-celled form or as a colony of cells such as bacteria, fungi, and algae.

Read More

Preventative Maintenance

Avoid a Pipeline Freeze with a Methanol Injection Plan

As temperatures drop, equipments risk of damage increases.

Read More

Designed with You in Mind

Shop our complete line of Bulk Solid Samplers to find the right fit for your sampling application.